Army;

I guess my posting was somewhat simplified...those open, two crimp area terminals you show are also good, industrial quality, and similar to what Volvo used on the Amazon Headlight (and others) Hex connector (See:

http://www.sw-em.com/voltage_drop_in..._connector.htm ), but they

must be used in conjunction with the

very specific crimping tool, which crimps both conductor and insulation as a strain relief.

For instance, in the avionics industry, jaws of that tool would have been specified for gauge of the conductor, and material and OD of the insulation, and the tool would have a mechanical provision to assure crimp was completed and not stopped before it was completed to the end of excursion (I call that non crimpus abortus!), and the excursion was also limited to prevent overcrimping, in order for everything to be perfect...those tools cost hundreds of $...

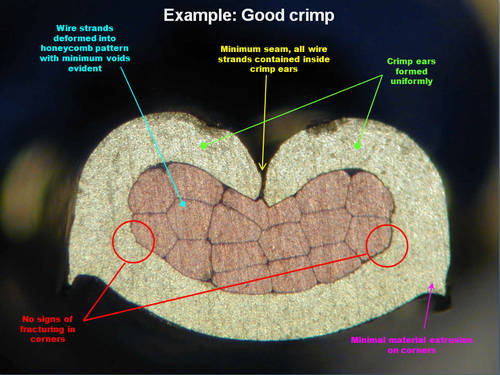

Conductor area of crimp should look like this in cross-section (and idealy, per my recommendation, with what minuscule air air-space is left, taken up by ACZP!):

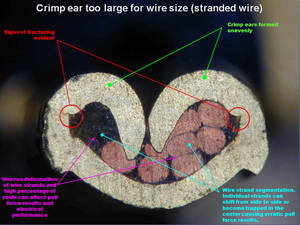

...not like this:

Source:

https://www.etco.com/engineering-guides/

Regarding that manual crimper Derek links...it looks to be a single dimple type which also looks like it should work well...I would recommend using it in a vice or arbor press or set it up hydraulically in order to have a high degree of control over the amount and excursion of force.

Once again, the point is made that with crimping, although a very simple operation, a lot can go wrong, so operator care, proper use of tools and inspection after the operation to assure finished product, are all quite important.

Cheers