|

|||||||

| 700/900 Series General Forum for the Volvo 740, 760, 780, 940, 960 & S/V90 cars |

Information

Information

|

|

97 940 2.3t stalling after blanking recirc, is there a fix?Views : 1240 Replies : 12Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Member

Last Online: Jan 1st, 2023 16:44

Join Date: Mar 2017

Location: Blackpool

|

Before I get the inevitable comments about how compressor surge is bad and it will reduce the life of my turbo etc etc, please understand I'm aware of all the risks and whatnot but would simply like to get an answer to my question.

So I recently blanked off the recirc valve on my 1997 940 2.3t simply because I like the sound it makes (yeah, i know...). But I have the issue that when I let off after accelerating, the revs often drop immediately and the car stalls. I believe this may be something to do with metered air not being recirculated but Im not entirely sure. I was simply wondering whether there is something I can do to stop the stalling, whilst keeping the blanking plate and turbo chatter? Thanks |

|

|

|

|

|

#2 |

|

🤍💙💗

Last Online: Today 16:58

Join Date: Mar 2006

Location: Lichfield

|

Mine is blanked off too. The idle control valve is blanked off too and I set the idle speed manually.

With a cone filter it stalled quite easily, with the stock airbox it doesn't. It's close (~500 rpm) but it just about keeps going.

__________________

MY97 940 CD LPT Super Sports Edition 2 Turbo, Midnight Purple, 175,000 miles.

|

|

|

|

| The Following User Says Thank You to baggy798 For This Useful Post: |

|

|

#3 |

|

Premier Member

Last Online: Apr 9th, 2024 21:44

Join Date: Jul 2009

Location: Holywood

|

The cause is a lean mixture caused by the remaining pressure in the the inlet.

The extra air is not recirculated (contrary to popular belief), the pressurised air leaves via the dump/recirc valve out through the air filter. Recirc means the valve is always open with the throttle closed, not that it recircs the pressurised air. You have to get the extra air out of the system to allow it to idle in closed loop. I did find that disconnecting the throttle closed switch offers a crude solution as it tends not to go into closed loop mode, but it runs pretty aweful. My experience with the stock air filter is that it will stall if there is no dump (eg dump valve diaphram is torn or pipe is off). I can't see why a cone will be any different, the stock is just quieter. The only proper way to manage it is to use a MAP management system, but even then I'm not sure you can restrict the air flow enough for it not to stall. But you might run it at high rpm with enough fuel to use it up for a few seconds. My advice is to put a cone filter in or open up the stock air filter, remove the sound absorbers to get some nice turbo noises, dumping and spooling but not so much flutter. One thing I have thought of is an electronic dump valve, that works with the throttle closed switch, but uses a time delay so it doesn't close for gear changes, but does for idle >0.5s or so. For drag racing say. Say you used a processor board like an ardiuno you could have different modes. Last edited by TonyS9; Jun 12th, 2018 at 11:45. |

|

|

|

| The Following User Says Thank You to TonyS9 For This Useful Post: |

|

|

#4 |

|

Senior Member

Last Online: Apr 12th, 2024 17:04

Join Date: Jul 2012

Location: Northwich

|

Pretty much either unblank it again or fit a dump valve in the boost pipes somewhere. Unless you really want to fit aftermarket management as stated above. The blanking plates are only meant to be used when you are fitting aftermarket dump/recirc valves

I've definitely noticed more noise from fitting a 16T in place of the 13C that was on there before, I'm also using my home made stainless 3" turbo back exhaust so it allows a bit more flow and noise. I'm 28 and personally I'd rather have reliability and good idle rather than nice noises (yes I agree it does sound good) and poor running/cutting out.

__________________

940 B230FT Last edited by Jimsiss; Jun 12th, 2018 at 14:48. |

|

|

|

| The Following User Says Thank You to Jimsiss For This Useful Post: |

|

|

#5 |

|

Premier Member

Last Online: Apr 9th, 2024 21:44

Join Date: Jul 2009

Location: Holywood

|

If the throttle body could hold the air back enough, you might be able to do something with the idle valve which is too open.

Either a time delay relay to close the idle (open circuit using a relay) or reduce it significantly to reduce the air flow for a few seconds. Using Arduino for a more complex map during depressurisation. Maybe try wiring in a switch to the ICV, or simply unplug it and use the accelerator to keep the engine going while you test how long it takes to stall with it in or out after accelerating. If it takes significantly longer, a simple ICV cut off for a second or 2, triggered by throttle close might do it. BTW I'm thinking that blanking the dump valve seems pointless, surely taking the pipe off will have the same effect. Then you might use a electrical valve solenoid to control it via the control pipe. |

|

|

|

| The Following User Says Thank You to TonyS9 For This Useful Post: |

|

|

#6 |

|

🤍💙💗

Last Online: Today 16:58

Join Date: Mar 2006

Location: Lichfield

|

__________________

MY97 940 CD LPT Super Sports Edition 2 Turbo, Midnight Purple, 175,000 miles.

|

|

|

|

| The Following User Says Thank You to baggy798 For This Useful Post: |

|

|

#7 |

|

Member

Last Online: Jan 1st, 2023 16:44

Join Date: Mar 2017

Location: Blackpool

|

Cheers for all the suggestions guys. Is the IAC valve adjustable? Never had to touch one before.

|

|

|

|

|

|

#8 |

|

Premier Member

Last Online: Apr 9th, 2024 21:44

Join Date: Jul 2009

Location: Holywood

|

No its not manually adjustable as such. It is a variable valve servo, so it can be controlled electrically. You can close it by disconnecting it (eg by a relay). The opening is proportional to the applied voltage.

The computer uses lean closed loop mode when the throttle is closed, it assumes a certain air flow with a certain opening voltage setting. It then slowly feeds back rpm and O2 sensor results, and adjusts the opening and fuel appropriately. The feedback is very slow so it can't take sudden loads or unknown extra airflow. It needs told about extra loads like AC or Auto drive select when they happen. The outputs (idle valve and injector pulse rate) can be changed quickly but sensing/feedback takes alot longer. |

|

|

|

|

|

#9 |

|

VOC Member

|

The compressor bypass valve is there to keep the turbo spinning when you lift off the throttle during gear-changes. Without the CBV the pressure builds up when the throttle plate closes, to the point when the turbine can't spin.

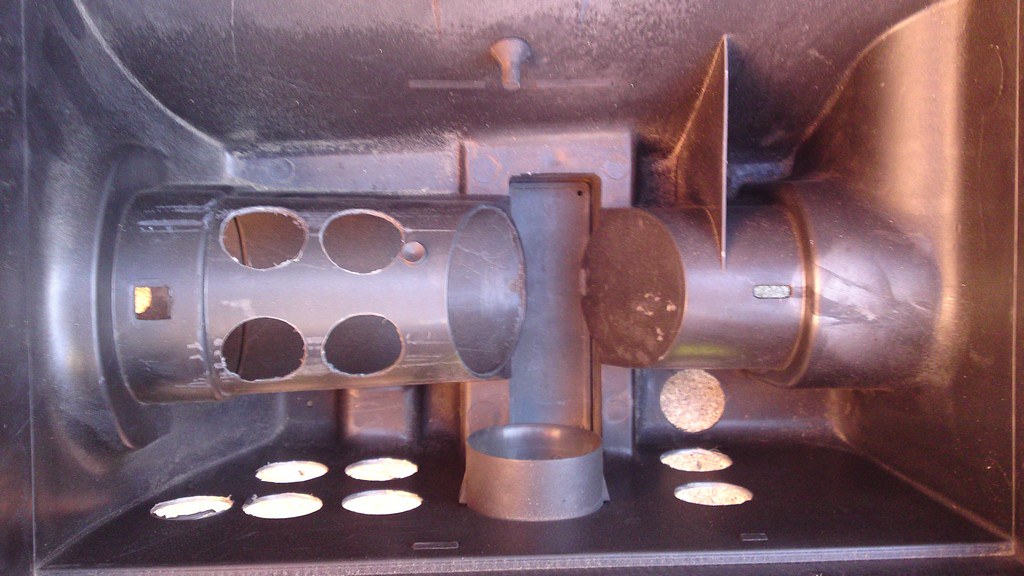

Your solution is to replace the CBV. If you want more induction noise a simple way is to modify the air filter housing below the filter to allow more air in and sound out.  I used a couple of different hole-saws to make it breathe more easily (the lpt air box only has a 50mm inlet as standard).

__________________

Gavin  1997 945 CD (B230FK) [RIP: 1991 945 Turbo (B230FT) 1992 945 SE turbo (B200FT)] |

|

|

|

|

|

#10 |

|

🤍💙💗

Last Online: Today 16:58

Join Date: Mar 2006

Location: Lichfield

|

The idle valve does have an adjustment screw set from the factory, but don't think that would have any effect on the stalling.

I removed the hoses leading to the idle valve and capped them using these stick ferrules from Wilkos. The idle valve has to be left plugged in otherwise the ECU throws a code.    Downside to this setup is during cold starts you have to press the gas pedal slightly for the first couple of minutes or it will idle at about 500 rpm, I usually start driving away within 30 seconds anyway. Not saying this is the best way of doing it but it's been like this for 5+ years and no problems.

__________________

MY97 940 CD LPT Super Sports Edition 2 Turbo, Midnight Purple, 175,000 miles.

|

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|