|

|||||||

| 700/900 Series General Forum for the Volvo 740, 760, 780, 940, 960 & S/V90 cars |

Information

Information

|

|

Engine won't rev and huntsViews : 21408 Replies : 509Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#291 | |

|

Premier Member

Last Online: Yesterday 23:33

Join Date: May 2012

Location: Lakenheath

|

Quote:

Reading through those ECU faults last night i noticed there was a reference to some power transistors as being the potential cause of a bad idle and/or not being able to rev over 3000rpm. I've just looked them up and they're readily available : https://uk.rs-online.com/web/p/bjt-b...stors/5449977/ Might be worth checking out if other tests prove fruitless.

__________________

Cheers Dave Next Door to Top-Gun with a Honda CR-V & S Type Jag  Volvo gone but not forgotten........ Volvo gone but not forgotten........

|

|

|

|

|

|

|

#292 | |

|

Senior Member

Last Online: Mar 25th, 2024 20:09

Join Date: Feb 2017

Location: Norwich

|

Quote:

|

|

|

|

|

| The Following User Says Thank You to ANDTWENTY For This Useful Post: |

|

|

#293 | |

|

Premier Member

Last Online: Yesterday 23:33

Join Date: May 2012

Location: Lakenheath

|

Quote:

I can explain how to do it when the time comes and is a non-destructive test so if you find the transistors are ok (assuming they're all the same, if there are different types then we may have to alter the test slightly) then it won't make any difference to the ECU so you won't be put back by it. It won't necessarily put you any further forward either but some photos from you of the solder side of the ECU PCB may be helpful come the time of opening it up. To explain what i mean, this is a headlamp control module from a 1989 Rover 827 Vitesse - in Sweden!  From that pic, i spotted two potential problems. As i pointed out to the owner of the relay (and the car!), it was a problem, i wasn't sure if it was the problem but certainly wouldn't help. However, by way of confirmation of the two problems, the owner sent back this pic :  I can't do the "draw a circle on an image" thing but the ring round the top two solder joints confirmed he knew where i was describing. The symptoms were no headlamps at all, no dip or main beam and no flash either. The owner resoldered those two joints then sent me this :  It's entirely possible that your (half-working) ECU has one or more dry joints in it, especially given the age of it. In the late 80s, the EU passed a Directive that effectively outlawed tin/lead solder in the workplace. Replacement "user-friendly" solders were developed (hurriedly!) that although they worked when new, several years or more down the line the solder joints failed. Things have improved since but anything electronic made in the late 80s/early 90s is susceptible to poor solder joints causing problems. Sometimes a dry joint can be capacitive as well. This means they will pass current up to certain frequencies then stop so your problem with the half-working ECU could well be nothing more than a solder joint that's gone dry. It's a possibility, no more, no less. Until all possibilities are investigated we won't know for sure unless something definite is found along the way.

__________________

Cheers Dave Next Door to Top-Gun with a Honda CR-V & S Type Jag  Volvo gone but not forgotten........ Volvo gone but not forgotten........

|

|

|

|

|

|

|

#294 | |

|

Senior Member

Last Online: Mar 25th, 2024 20:09

Join Date: Feb 2017

Location: Norwich

|

Quote:

I remember a guy I bought my other Volvo off telling me that Volvo had issues with solder joints going bad because of the change in regulations. My multi meter is just a big standard one from Screwfix so if it doesn't do that I'll grab another one if needs be |

|

|

|

|

| The Following User Says Thank You to ANDTWENTY For This Useful Post: |

|

|

#295 | |

|

Premier Member

Last Online: Yesterday 23:33

Join Date: May 2012

Location: Lakenheath

|

Quote:

General rules of thumb for a dry joint is an uneven joint, a dark ring in the solder, usually part way down the joint, a darker, mottled effect to the joint or even a rough surface in the joint and usually a darker, less shiny colour. One of the images i found suggested the cure was a soldering iron and a blob of solder!   Proper remedy is heat the joint up, add a little fresh solder so the flux inside helps the old one to flow, use a desolder pump aka "solder sucker" to remove the old solder while still molten then apply new solder to the hot joint. It should flow nicely and produce a nice shape giving good adhesion to the board and the pin, leaving a bright and shiny joint when cool. It needs to cool naturally as blowing on it for example is likely to produce a dry joint. If you don't remove the old solder, there's every chance some of it will remain and as it's the "EU type" that causes problems, that means it's sitting there waiting to cause another problem in the future.

__________________

Cheers Dave Next Door to Top-Gun with a Honda CR-V & S Type Jag  Volvo gone but not forgotten........ Volvo gone but not forgotten........

|

|

|

|

|

|

|

#296 | |

|

Senior Member

Last Online: Mar 25th, 2024 20:09

Join Date: Feb 2017

Location: Norwich

|

Quote:

I did try opening them but can't seem to on my phone as I'm at work so will check tomorrow when im home to see bit yea I'll pop some pictures up as you may notice something I don't. Thinking about that symbol you sent for the multi meter would that be what I use for continuity? From memory it looks similar. I don't have a solder sucker but can't think they are very expensive so if needs be I'll grab one, think I may have one at home as my brother used to do the odd bit of soldering and stuff. Rather pop new on and know it's done properly that just add more or re heat it. |

|

|

|

|

| The Following User Says Thank You to ANDTWENTY For This Useful Post: |

|

|

#297 |

|

Premier Member

Last Online: Yesterday 23:33

Join Date: May 2012

Location: Lakenheath

|

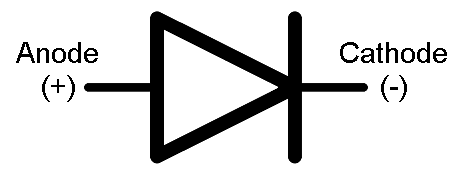

Yes, there's usually a continuity buzzer built into the diode test function and besides the diode symbol, there's usually a buzzer symbol, three of four little curved lines, each bigger than the other.

https://www.ebay.co.uk/itm/Professio...r/312514657146 They're cheap enough, don't know what soldering iron you have access to but preferably a temperature controlled one with a fine tip, about 30W or thereabouts is more than enough.

__________________

Cheers Dave Next Door to Top-Gun with a Honda CR-V & S Type Jag  Volvo gone but not forgotten........ Volvo gone but not forgotten........

|

|

|

|

|

|

#298 | |

|

Senior Member

Last Online: Mar 25th, 2024 20:09

Join Date: Feb 2017

Location: Norwich

|

Quote:

Yea not too expensive, will see if I can pick one up from Screwfix or tool station tomorrow I have 2 plug in soldering irons, ones a lower wattage I think but I've also got a gas one which I can control the temperature on and has a more pointed tip so probably use that Last edited by ANDTWENTY; Oct 3rd, 2019 at 21:39. |

|

|

|

|

|

|

#299 |

|

Member

Last Online: Mar 26th, 2024 18:43

Join Date: May 2009

Location: Wembley London

|

Hi Dave and OP. As I have a similar 940, I've been following the progress, and learning a lot, as things go forward. In another thread, there was the suggestion that the odd 'red herring' or 'spanner in the gearbox' type of post sometimes helps things along, if only by freeing up the minds involved in the problem, and allowing them to step away from the current state of play. Apologies in advance if I'm completely barking up the wrong tree, or just 'barking' even...

Without going through the entire thread, I think it may have been said that the charging was in the 16 volt region? And that this could be down to a poor alternator regulator (or it's connections), and/or, the use of a calcium battery. It makes me wonder why this car came with such a battery? Does this point to this area having been a problem area with the car previously, and then someone whacked whatever battery was available in to the car? Is there any reliable history of what happened to the car? I can appreciated that any lead acid battery will do in an emergency (almost), but the one chosen may not help. To that end, I would want to see more typical voltages, so I'd stick (borrow) a more conventional battery in there, and if that didn't sort the voltage then move to asking the alternator, and it's regulator to behave! The slightly high MAF voltages might or might not be related to the above. At a guess, the MAF gets it's nominal 12 volts (or in this case 16 ish volts) , regulates this locally (as well as it can), then gives an output in the 0 to 5v range, which informs the ecu. And how robust is the voltage regulation within the complex (sub) circuits in the ECU? I appreciated that provision will be made for the hostile and spikey nature of the available supply, but continuous over voltage? And what if something else didn't like the over voltage? I mention the above stuff only because substantial efforts have been made to ensure that basics are as they should be! The other herring on offer, (and this will more show further lack of knowledge on my part) is the integrity of the intercooler hoses and junctions. I can't find any posts on the subject to improve my understanding (I wish I could), but I don't have any other names for these hoses! Last time I was at Lakes (breakers), getting some little bits of trim, I mentioned some slight misbehavior that I was having with my car. Barry flipped the bonnet and (amongst other things), said that there can be a crack just behind the junction of the turbo air output hose, and the hose going across the head to the PCV. And when this cracks, air leaks and upsets things... Cleaning my cars throttle body and the IACV again are long over due, so I'll do that again soon. Apologies again, in advance, if I'm way off the mark on either of these concerns. I look forward to you guys getting to the bottom of this naughty engine! I don't believe in being intimidated by a car, any car... |

|

|

|

| The Following User Says Thank You to arctan For This Useful Post: |

|

|

#300 | |

|

Senior Member

Last Online: Mar 25th, 2024 20:09

Join Date: Feb 2017

Location: Norwich

|

Quote:

Thank you very much for this post! I know myself from other projects that you can get stuck in o e way of thinking and short sighted on one thing so it's good to have so other ideas that perhaps people may not have thought of. As for the battery and alternator, this to me seems high but I didn't know that it's normal for some battery types to receive high voltages from the alternator. I assumed it was just a standard Volvo issue battery as it's got a Volvo sticker on it and he had the car serviced at Volvo and used all Volvo parts. I'll have a look through the paperwork to see when this battery was put in, perhaps it coincides with the rough time the issue could have started although this is unknown. I have another battery in the garage, just a standard lead acid one I believe so could pop this on charge and see if it makes any difference to the voltage output on the alternator. Laird said how it could be a smart alternator so if this is correct then the voltage should drop!? I see no harm in trying so might be worth a shot although between having a broken alternator and the battery charging up I'd have thought at some point it would of run okay if this was the cause. When I first put the alternator on I recall it only being about 14.6V so perhaps it's gone funny since. As for the turbo pipes being an issue mine is a non turbo so it doesn't have an intercooler or subsequent pipework so this won't be at fault on mine. One of the first things I did though was check for air leaks on the intake ducting as suggested by laird and perhaps others and I couldn't find anything so I don't think this is the issue. All the sensors seem to test okay apart from the MAF which is high and the temperature sensor which I'm yet to test so this has led me to the ECU playing up. |

|

|

|

|

| The Following 2 Users Say Thank You to ANDTWENTY For This Useful Post: |

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|