|

|||||||

| 140/164 Series Articles How to's and Guides for the 140/164 series. |

Information

Information

|

|

Vinyl seat repairsViews : 14979 Replies : 0Users Viewing This Thread : |

|

|

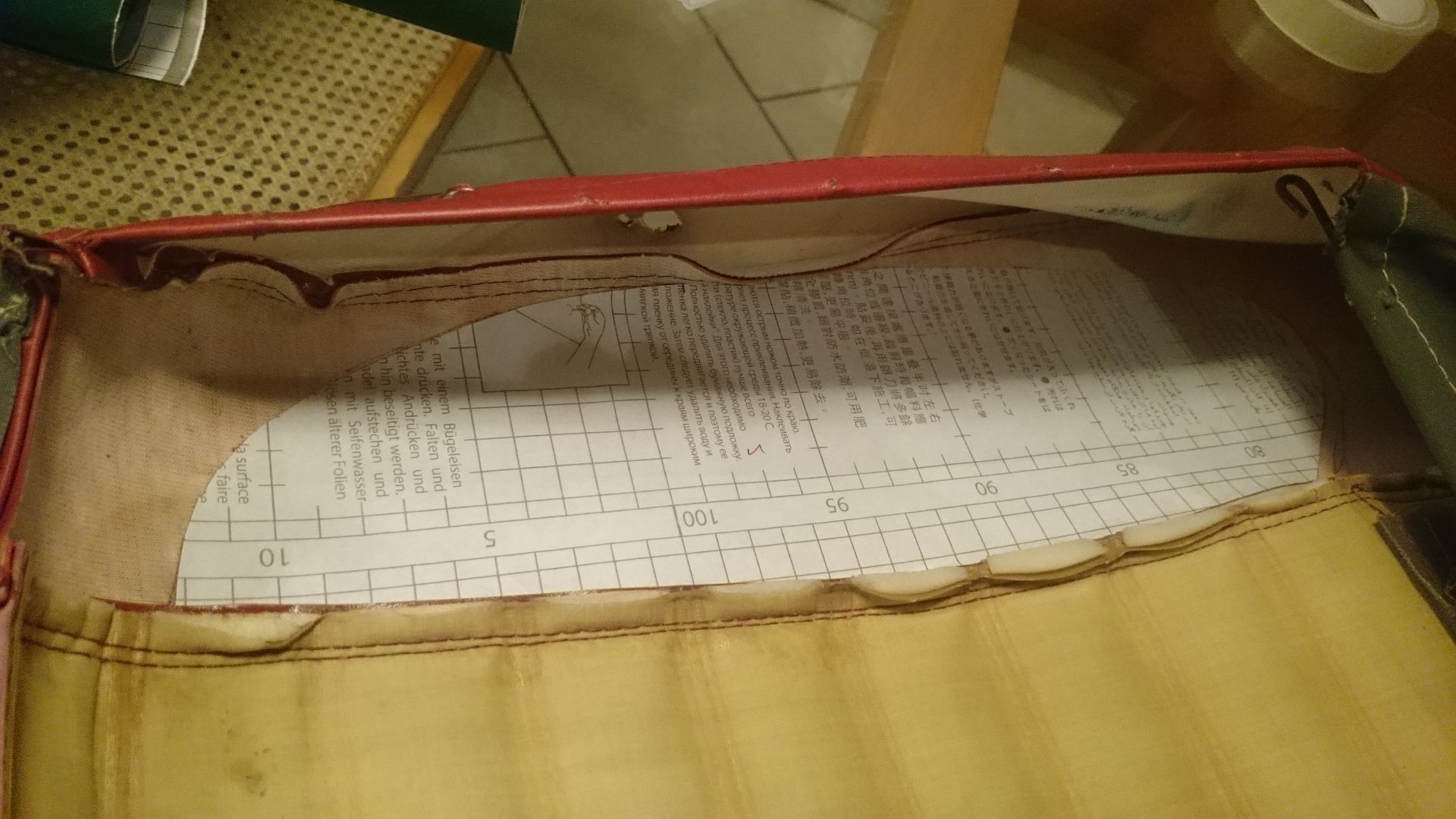

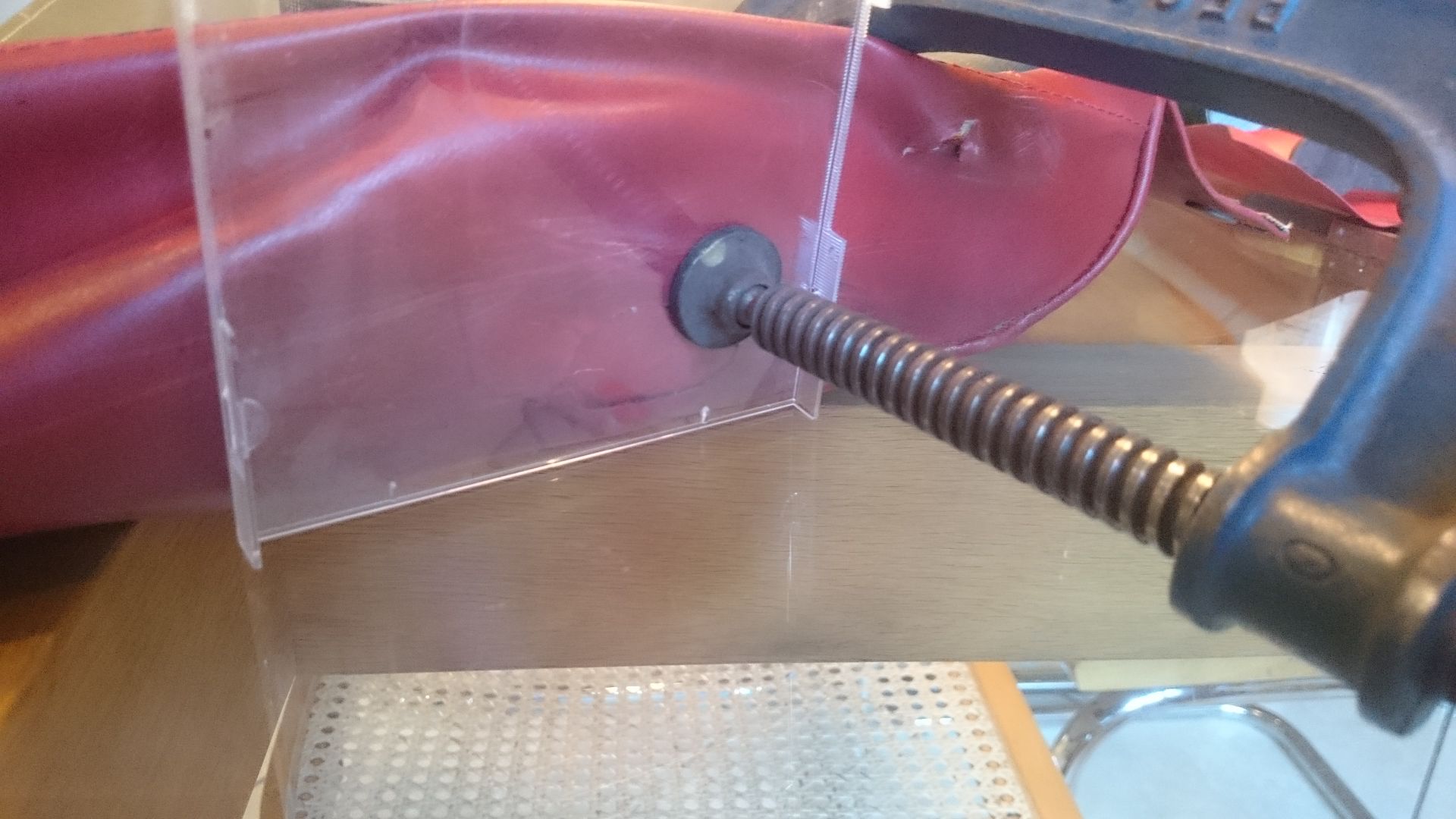

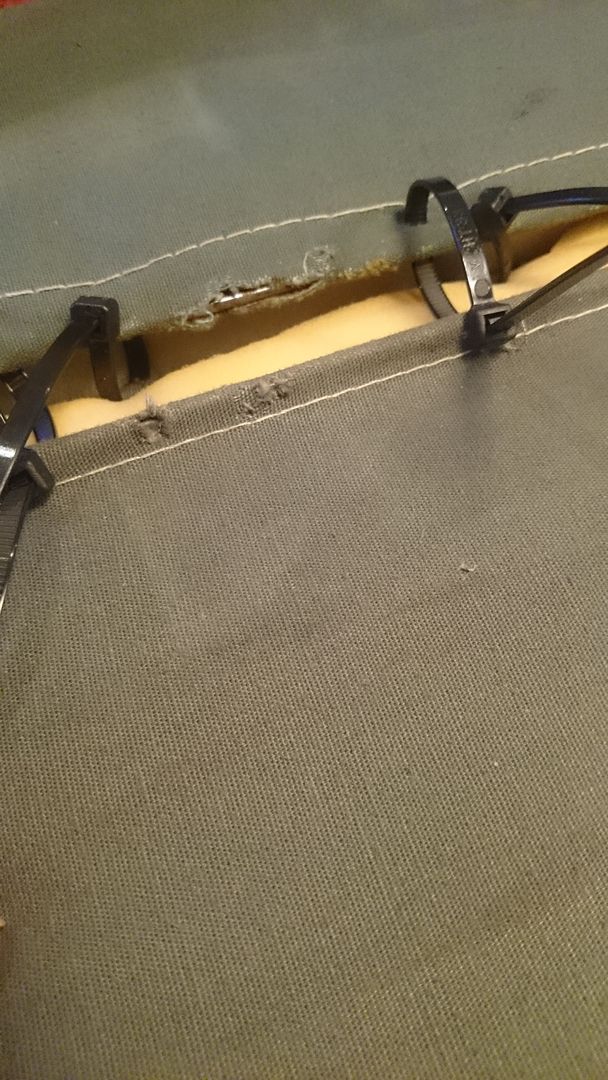

|

Thread Tools | Display Modes |

|

|

#1 |

|

VOC Member

|

Vinyl seats: DIY repair of minor damage

My 144 had some wear and damage on the front seat cushion   I swapped the left and right cushions, to even out the wear, and repaired the damaged one. It's not perfect, but looks fine in the car I used Furniture Clinic products, including glue, filler, surface prep and colourant matched to a sample I posted https://www.furnitureclinic.co.uk/ Other than being a customer, i have no links to the company. I believe there are good alternative products available. This is a DIY guide, it does not give a perfect or invisible repair. 1. Remove the cover from the foam by cutting or twisting off the metal clips 2. Work on one repair at a time, it would have been too difficult to repair the splits and the hole together. I taped across the splits, at intervals, to hold the sides together. I glued the sections I could access, then when dry removed the tape and glued the remainder of the splits. Take care because the repair is quite fragile at this stage  3. I put two layers of glue on the inside, worked thoroughly into the backing of the vinyl, letting them dry  4. I then glued a reinforcing piece on the inside, over the whole of the damaged area. Use flexible - but not stretchy - fabric, to help avoid the splits being pulled open again. I used felt I had left over from the glovebox retrim. I used spray on contact adhesive for this part  5. To repair the hole, I cut of the jagged edges, then glued and clamped a repair piece on behind. I used clear plastic at the front of the clamp, so I could see to avoid folds and wrinkles. I used Carbond940 for this. Messy to use, but strong, and it stays flexible   6. Before finalising the surface repairs, the next stage is to refit the cover to the foam. But in this case, the way the seat had originally been assembled had pushed the foam into the wrong shape  I trimmed the sides with a serrated carving knife, so give a neater edge  7. Instead of the metal hooks originally used, I always reassemble seats using cable ties. It's a much easier process for the amateur, because the joints can be tightened gradually to pull the cover into the correct alignment. For easier lining up I mostly I reuse the holes that the metal hooks went through. The exception is where the fabric has worn or rotted, where I make new holes.   8. With the cover fitted, I fill any gaps and shape the repairs as much as possible. It's a slow process, because the water based filler has to be built up in several thin layers, with each being allowed an hour or so to dry before the next   9. I then sanded down the worst of the high spots with 1200 wet and dry paper, being careful not to loose too much of the 'grain' moulded onto the surface, or to make the vinyl too thin thin anywhere. When using colourant, it's vital to follow the maker's instructions for surface cleaning and prep. (No point repeating all that here, it comes with the products, but it involves alcohol cleaning, keying the surface, and applying adhesion promoter). The first layer of colour is sponged on. It's usual for it to look bad at this stage!   10. For the next stages. I used a spray gun. - Localised colour to cover the repairs - All over sealant to project the colourant and give a uniform finish The colour match can't be perfect on this type of vinyl, because the original has a base colour with a slight dark 'dappling' printed over the top. A repair product can't replicate this exactly. My repairs aren't invisible, but all in all it's good enough for a satisfactory repair    Hopefully this guide will help preserve some old Volvo interiors! Last edited by foggyjames; Jan 7th, 2018 at 23:48. |

|

|

|

| The Following 11 Users Say Thank You to john h For This Useful Post: |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|