|

|||||||

| PV, 120 (Amazon), 1800 General Forum for the Volvo PV, 120 and 1800 cars |

Information

Information

|

|

distributor drive problemViews : 401 Replies : 3Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Master Member

Last Online: Yesterday 14:30

Join Date: Jun 2007

Location: tunbridge wells

|

Having installed rebuilt engine in my Amazon I am finding it hard to get the distributor drive to locate . It goes in ok and twists as it should when it connects with the camshaft but the bottom is not locating into the oil pump drive so the distributor clamp is not sitting level with the block . I have tried locating it through all permutations of 360 degrees and it just wont pop down .It a b18 block thats been bored out and a K cam . So long since I had it done Ive lost the build sheet . There was no drive in the engine when i got it back but i can see at TDC the groove it should sit in is roughly at 02/40 if it was a clock face looking from the nearside of the engine ,hope this makes sense ??

Any suggestions anyone please ? Happy Xmas and thanks in advance |

|

|

|

|

|

#2 |

|

VOC Member

Last Online: Yesterday 15:54

Join Date: Jul 2006

Location: Chatham

|

It may or not be your issue but note that the drive slot is offset to match what you will see if you look at the drive on the bottom of the distributor drive shaft.

|

|

|

|

| The Following User Says Thank You to Derek UK For This Useful Post: |

|

|

#3 |

|

Premier Member

Last Online: Yesterday 11:51

Join Date: Jul 2007

Location: Connecticut, USA

|

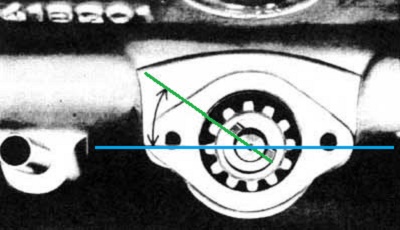

R122;

Use a flatblade screwdriver to initially rotate driveslot of Oilpump to an approximate correct rotational position (get that angle by looking at Drivepawl, while holding Shaft in the desired TDC No1 position) before dropping in Dist Driveshaft (and remember that it will turn as it engages the bevel gear of Cam, so rotate it in the opposite direction a tooth or two before engaging Cam). Then turn Crankshaft slowly, back and forth (looking for alignment, and "drop-in"), while keeping a gentle downforce on the Dist Driveshaft, until they line up and it allows Drivepawl to drop into Slot... Once it drops in and engages, rotate the engine further in the normal direction, to TDC No1 and see if it is the standard position as seen here:  ...if not, pull Dist Driveshaft, rotate in the favorable direction to achieve this, then repeat...since there are a number of teeth on the Camshaft bevel gear, it may take more than one iteration to get there. I hope this explanation is understandable (and answers your question!)... It is good practice to check Dist Drivepawl to Oilpump driveslot fit before engine is assembled (particularly if and when there is a reinforcing ring installed on Oilpump), to assure no clearance issues once things are assembled and access is limited... Good Hunting, and Merry Christmas! Edit: Derek's and my post crossed in the ether, but I think we are saying the same thing... Last edited by Ron Kwas; Dec 25th, 2019 at 00:03. |

|

|

|

|

|

#4 |

|

Master Member

Last Online: Yesterday 14:30

Join Date: Jun 2007

Location: tunbridge wells

|

Thank you very much Ron. I hadn't thought to alter the angle of the oil pump slot and when i did it was easy to get the slot in the right direction at TDC . A little gentle rocking of the crank and it dropped in no problem .

Another job done ,thanks for your assistance ! Alan |

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|