|

|||||||

| PV, 120 (Amazon), 1800 General Forum for the Volvo PV, 120 and 1800 cars |

Information

Information

|

|

1966 Volvo Amazon engine transplant!Views : 23645 Replies : 145Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#121 |

|

Master Member

Last Online: Nov 29th, 2020 00:42

Join Date: Feb 2010

Location: Newton Abbot

|

Don't want to try to teach you to suck eggs but a really good forum with lots of advice, i still refer to it now and again as i don't weld too often:

http://www.mig-welding.co.uk/tutorial.htm And something else i do is run a few beads on different settings on a small piece of steel 4" by 4" and once i am happy with the beads i write on it the settings used for each one power,wire speed and gas flow rate then next time i get the welder out i can just get it set up straight away in case someone else has had a fiddle with my settings or it has been knocked by accident. Looks like you are enjoying it anyway

|

|

|

|

| The Following User Says Thank You to Tail For This Useful Post: |

|

|

#122 | |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

Quote:

His welding style is not to just hang on to the trigger. 10 years of welding up rusty cars with thin metal means this is how he does it to avoid blowing through. My friend does the opposite. Just personal preference I guess, and I imagine it also depends on what your welding. I prefer Phil's method personally but actually just so I can see where I'm going otherwise I end up welding the bit next to where I need the weld  although that's just cause I'm an amateur. although that's just cause I'm an amateur.

Last edited by Melody121; Jun 1st, 2015 at 12:47. |

|

|

|

|

|

|

#123 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

I've had a really busy couple of afternoons. I've made all the panels, Phil has welded a couple of them in, and I've cut the rot out the drivers side to patch up. All thats left to do is clean up the drivers floor and everything can get welded in.

Cause a picture says a thousand words, here goes!    Chop!  Rustproofing!   And the inside closing panels too   Good progress! I'm really happy, no more welding now till Saturday but lots more prep to do and I can start on engine stuff yay! |

|

|

|

|

|

#124 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

I've been bitting and bobbing over the last couple of days as we've not had a chance to get the welder out again yet, that's hopefully tomorrow....

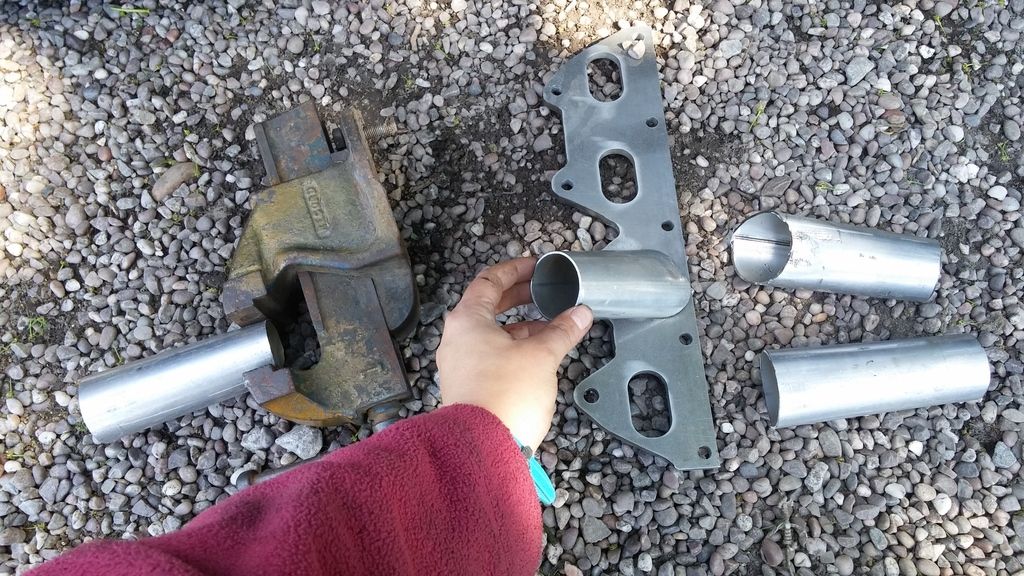

I finished off the inner arch and ns bulkhead with a splash of paint and some stone chip and underseal. I think I'll probably repaint the whole bay when i get a bit closer to finishing.   I found a bit more rust in the floor to cut out and make a patch for.  Then I started making my inlet manifold. The lesson I learnt here was squish first, cut second, in case anyone else wants to attempt this. I finished one tube messed up a second tube squished a third tube and started the last one before I ran out of strength!  Then I measured up my propshaft, the two ends just want welding together and that'll be that ready to fit.  Then I made some spacer plates for my gearbox mount, as I noticed when fitting the propshaft that the gearbox is sitting about 5mm too high. So 3mm steel two each side and that should be that fixed! Although this stuff eats drill bits, so that another job half done   Then last but not least, I gave her a wash, as she's now sat under a tree getting filthy. And bought a nice cover so she has a chance of staying clean!

|

|

|

|

|

|

#125 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

I've not had a lot of chance to do anything this week. Went to Renishaw Car show Wednesday, had a job interview yesterday (need full time money again, even though Olga is loving the part time me) and had to nip to work today to give them my notice.

I did manage to finish all the pipes for the inlet manifold though so their ready to be welded on. Then I had time to fit a door seal. This particular door has never had one while I've had the car!    Pray for no rain this weekend so some welding can get done!!! |

|

|

|

|

|

#126 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

Ironic.

Managed to find somewhere to shelter from the rain Sunday and the welder immediately ran out of gas...... Will pick some more up Wednesday! |

|

|

|

|

|

#127 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

Today I requested a welding lesson as Phil hasn't had much time for welding so I want to do some myself. I have had a lesson off him a few years ago but I didn't have the confidence to have a go without another.

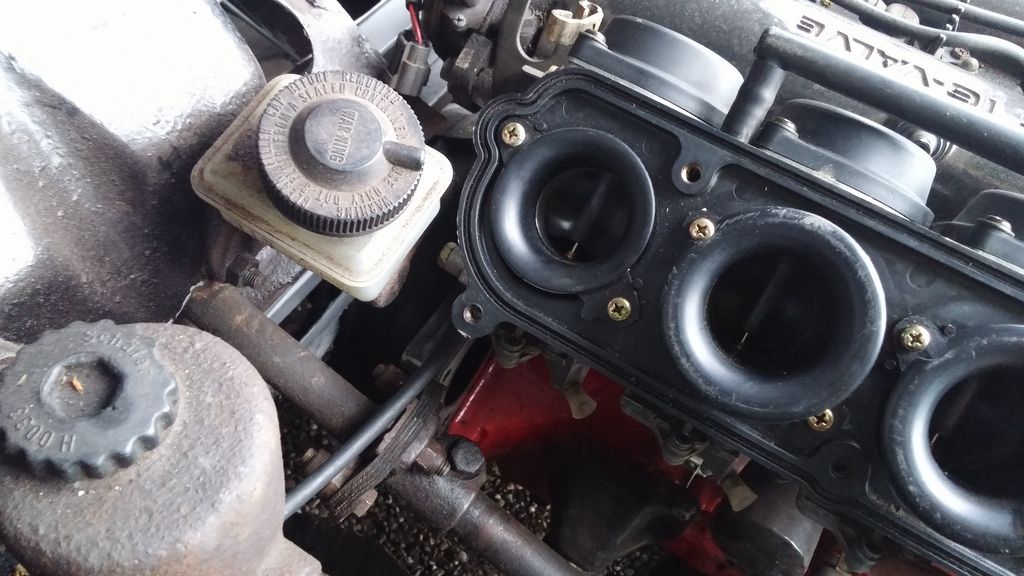

So for a quick summary, lesson start and attempt one;  Whoops, thats a bit pants! Attempt two was good enough I've got enough confidence to have a crack at the car tomorrow now;  Then while the welder was out Phil buzzed round the inlet manifold. Soooo happy this bit is done it feels like a small amount of work for a huge gain.... Pics.....    And by some miracle it all clears everything. Woo! Virtual high fives all round

__________________

1966 Volvo Amazon - Olga 1995 TVR Chimaera - Trevor 1998 Harley Davidson 883 Sportster - Harliquin 2000 Mercedes C180 - Claus |

|

|

|

| The Following 3 Users Say Thank You to Melody121 For This Useful Post: |

|

|

#128 |

|

Member

Last Online: Dec 15th, 2015 20:17

Join Date: Jan 2014

Location: Chesterfield

|

Life is getting a bit in the way of this beast at the moment. I've hurt my back which is just getting better just in time to move house this weekend

But my mate got a new welder and was dying to try it out so I gave him the propshaft  I'm very happy with it!

__________________

1966 Volvo Amazon - Olga 1995 TVR Chimaera - Trevor 1998 Harley Davidson 883 Sportster - Harliquin 2000 Mercedes C180 - Claus |

|

|

|

|

|

#129 |

|

Master Member

Last Online: Oct 1st, 2023 14:39

Join Date: Dec 2004

Location: leics

|

love what you are doing, but please please be ultra careful with a "DIY" welded prop, these things need proper balancing etc etc.

|

|

|

|

|

|

#130 |

|

VOC Member

Last Online: Yesterday 14:29

Join Date: Jul 2006

Location: Chatham

|

I would also add that the amount of "necking" at the join will reduce the strength in that area. No, I don't know what is under the primer, but another example of bad practice IMO.

|

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|