|

|||||||

| PV, 120 (Amazon), 1800 General Forum for the Volvo PV, 120 and 1800 cars |

Information

Information

|

|

Rule of nineViews : 2620 Replies : 37Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#21 | |

|

Master Member

Last Online: Yesterday 22:45

Join Date: Jul 2020

Location: Saskatchewan, Canada

|

Quote:

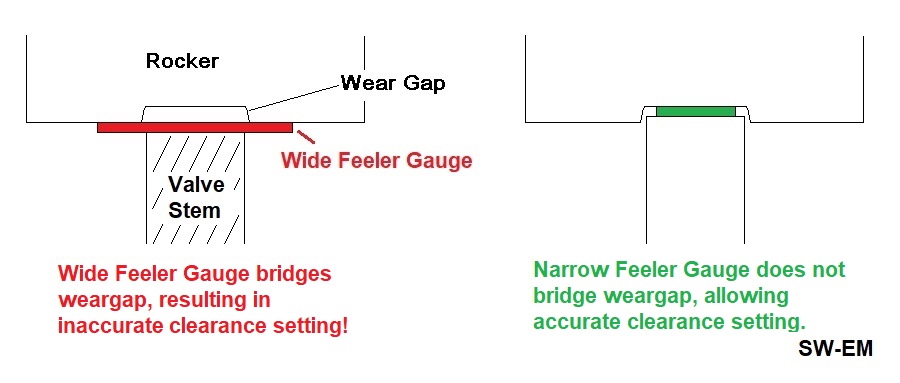

For those newish to the game, the bigger factor is the feeler gauge used to set rocker clearance. If you have an engine that has not had its rockers reprofiled in the last 10 - 20 k miles do not use a conventional flat feeler gauge. The rocker shoe develops a wear groove where it contacts the valve stem tip. You need to use a feeler gauge with a fine Vee tip and insert the gauge from the side of the valve (don't attempt to move the gauge front to back). You need to measure the clearance between the tip of the valve and the worn area on the rocker shoe. A large fat feeler gauge will give you the clearance between the tip of the valve and the unworn surface of the rocker shoe with the result that your actual clearance will be greater than the measured clearance. |

|

|

|

|

| The Following 2 Users Say Thank You to 142 Guy For This Useful Post: |

|

|

#22 |

|

Premier Member

Last Online: Today 00:11

Join Date: Jul 2007

Location: Connecticut, USA

|

Forum;

RoN requires me to remember some abstract rule...I don't bother because its all right there in front of me...staring at TDC#1 -Valves for No1 get adjusted, then I turn Crank 180Deg, adjust Valves for No3, then turn to Timing marks to TDC again (which is No4), adjust Valves, and finally, 180 Deg to No2, and adjust those...done! ...the only thing to remember is firing order... I wasn't going to chime in on this much ado about nothing, but now I would like to thank 142 guy for mentioning an important factor: The error due to Rocker Wear Gap ...this adjustment error can simply be eliminated by narrowing your feeler gauge to less than Valve OD, like so:  Source: https://www.sw-em.com/service%20notes.htm Cheers |

|

|

|

| The Following 3 Users Say Thank You to Ron Kwas For This Useful Post: |

|

|

#23 |

|

Bigbunt

Last Online: Apr 17th, 2024 22:13

Join Date: Apr 2014

Location: Guilford, Connecticut

|

Thanks Ron.. the visual seals the deal. That's what I was remembering about the narrow feeler. Didn't mean to make a big deal of the valve clearance...I just got a little torqued about "other" comments. Nonetheless, good little reminder of this wear issue.

Right now I'm just trying to rebuild my crushed car shed before the New England winter settles in! |

|

|

|

|

|

#24 | |

|

marches on his stomach

Last Online: Feb 11th, 2022 03:15

Join Date: Jan 2018

Location: Somewhere in the Netherlands

|

Quote:

...but if we're delving into details I'd like to make the following points:- 1) It seems like I've become an avid collector of feeler gauges - in an attempt to "always be able to find a set" I've ended up collecting many. All of the commonly available sets I have, have tapered ends and a final rounded tip that's about 5mm wide. In my experience this width is comparable with the contact areas (you are meant to measure for maintenance purpses) in most automotive valve trains. In practice I think it would be difficult to replicate the left hand situation in your graphic - but fair enough - it is something to consider 2) In my experience even the best engine builders seem to pay very little attention to the "actual contact" surfaces in valve trains. Sure people look at the wear of parts when dismantled but they tend not to focus on how these parts actually fit together. On many different engine types I've noticed that if you shine a torch on one side of the engine and look through the clearance the gap, more often than not the contact is visibly out of whack. With experience you can feel this with feeler gauges - you can feel the unevenness of clearnace gaps. This is not necessarily wear at the clearance gap. In my experience this is due to poor fitting parts and wear at the pivot points. Keep an eye out for new parts - rocker arms for example are not always as nicely reamed as they should be (yes FEBI - I mean you - sorry Mercedes reference...) ###### In the past when I have rebuilt engines I have done my best to make sure that the valve clearance gaps are as even as possible when I have been reassembling with new parts:- It takes a lot of time. I'm guessing that's why many engine builders - even the good ones - prefer to spend their time and your money polishing valves and porting heads instead of select fitting rocker arms! ###### If people wish to delve into the detail of these mechanisms I think their time is best spent considering the wear of the pivoting parts and ensuring the lubrication of the top part of the engine is working correctly. For the old fashioned push rod engines that more often than not in modern traffic have to work a bit harder than the more modern engines (with camshafts positioned higher up closer to the valves) I think that looking for bent push rods is a good plan. ###### I'm NOT saying people should be taking valve train components apart with frequencies of the valve adjustment service intervals. After removing spark plugs / glow plugs on diesel engines - simply watching the valves rise and fall as you turn the crank and making sure the distances are similar whilst you are adjusting valve clearances is more than sufficient. I'm just saying "look at the trees and the wood"! When you are adjusting or checking a particular valve clearance I think giving a rocker arm a sideways wiggle is also worth while. Compare that feeling with the others. If you find one that is particularly loose it might be worth your time taking things to bits to see if there is trouble, If your valve train is rattly - particularly after you have adjusted the valves - stop! Think about it! Perhaps you need to have another look at it...

__________________

1961 Volvo PV544 the quick and easy in between project(!) 1981 Mercedes 300D <=> 230 diesel to petrol conversion project 1965 Series 2a Station Wagon mega build 1992 Mercedes 190E The car that works!

|

|

|

|

|

| The Following 2 Users Say Thank You to Army For This Useful Post: |

|

|

#25 |

|

Premier Member

Last Online: Yesterday 12:22

Join Date: May 2012

Location: Lakenheath

|

Something not yet mentioned is feeler gauge technique. Many people don't get them exactly square to the gap they're measuring and don't realise there will be friction on the blades as they are dragged through the gap. They won't fit in if the gap is too tight but will drag a lot if it is correct. A smooth, easy sliding fit means the clearance is loose as there is obviously clearance for the blades which there shouldn't be when measuring the gap.

__________________

Cheers Dave Next Door to Top-Gun with a Honda CR-V & S Type Jag  Volvo gone but not forgotten........ Volvo gone but not forgotten........

|

|

|

|

| The Following User Says Thank You to Laird Scooby For This Useful Post: |

|

|

#26 | |

|

Senior Member

Last Online: Apr 9th, 2024 10:10

Join Date: Jan 2014

Location: stranraer

|

Quote:

|

|

|

|

|

|

|

#27 |

|

marches on his stomach

Last Online: Feb 11th, 2022 03:15

Join Date: Jan 2018

Location: Somewhere in the Netherlands

|

@Underdrive

(I was doing my best to ignore the post that you quoted) I completely agree with you. After my personal experiences I have also been known to describe the country mentioned in post #2 in a much more derogatory way... ...however... ...this is a technical forum. I do my best to try and avoid subjects such as politics because such subjects can sour a forum and start needless ego rectifying actions that spill over into the technical domain. This is not "my" forum I'm not in charge But I for one really would prefer not to see such posts.

__________________

1961 Volvo PV544 the quick and easy in between project(!) 1981 Mercedes 300D <=> 230 diesel to petrol conversion project 1965 Series 2a Station Wagon mega build 1992 Mercedes 190E The car that works!

|

|

|

|

| The Following 4 Users Say Thank You to Army For This Useful Post: |

|

|

#28 |

|

Member

Last Online: Jan 23rd, 2024 07:52

Join Date: Nov 2010

Location: Cape Town

|

Who needs a feeler gauge?

16 threads of a tappet screw span a distance of 17mm. Which means: For the required valve clearance of 0.50 to 0.55mm (B20B engine), you need almost exactly half a turn (28 to 31 minutes of arc, to be more exact). Therefore: Loosen the lock nut; turn the tappet screw in lightly until it touches the valve stem; turn it back out half a turn; nip up the lock nut again (while holding the tappet screw with a screw driver to keep it from turning); and you’re done. No worries about “Rocker Wear Gap”. |

|

|

|

|

|

#29 |

|

Premier Member

Last Online: Today 00:11

Join Date: Jul 2007

Location: Connecticut, USA

|

Simon;

...a great observation and comments...I'll have to try that next time, but it shows once again, that when you know what you're doing, or even have thought about things a bit, you can come up with multiple workable (and perfectly acceptable!) solutions... Cheers |

|

|

|

| The Following 2 Users Say Thank You to Ron Kwas For This Useful Post: |

|

|

#30 |

|

VOC Member

Last Online: Apr 18th, 2024 17:06

Join Date: Jul 2006

Location: Chatham

|

The Gunson Clickadust version of the original SPQR too works on that principle.

I've commented before on Ron's reasoning on grooved rockers. I've never see anything other than a shiny witness mark. The surfaces are hardened. Not long ago I did a light smoothing to a set I had on the shelf. Easy to do. That was to replace the ones on my Estate as I thought they might need a little TLC. When I took those off they looked just the same as the ones I'd refurbed. I think I posted some pics. I think I also asked for people to check any that they had or were willing to take off their engine. I asked for pics if they found any worn into a trough. No pictures were forthcoming. I'll repeat that request. Do you have pics Ron? I've seen this fault in diagrams on the web but have not seen any actual picture of it in the metal. It would have to be caused by lack of oil to the rockers along with considerable neglect over a long period. IMO. |

|

|

|

| The Following 3 Users Say Thank You to Derek UK For This Useful Post: |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|