|

|||||||

| Performance Volvo Cars A forum for those interested in any Volvo performance car from any era, FWD, RWD and AWD! |

Information

Information

|

|

320bhp N/A 5 cylinder engineViews : 62865 Replies : 124Users Viewing This Thread : |

|

|

|

Thread Tools | Display Modes |

|

|

#41 |

|

Junior Member

Last Online: Jun 28th, 2016 13:32

Join Date: Feb 2008

Location: Lincolnshire

|

I dont understand why the valve stem was so small if they were only running 8500rpm

The extra head flow from the waisted stem would be very minimal Valvetrain weight is not an issue at those type of rpm's Also cant understand why they went so big on lift (21mm) max valve flow is achieved at approx 1/4 valve diameter, the largest valve six I have managed to fit in a B5 head is 35mm diameter There were engines in th BTCC running 4 cylinders and similar power with far less spec than that Sounds like alot of bull**** to me IMO Also the lobes on those cams only look like 14mm lift as the base circles are quite large Raceco in the UK are getting over 300bhp out of the new 4cyl duratec engines with oversized valves, and 14mm 300 deg plus cams etc. http://www.raceco.com/ |

|

|

|

|

|

#42 |

|

300 Register Keeper

Last Online: Apr 24th, 2024 09:13

Join Date: Dec 2001

Location: Nottingham

|

I'm inclined to agree...or at least be suspicious that 825thou lift is a typo, especially on a multi-valve head. The burliest cam I think I've ever seen in a TwoValveEvo head (for a redblock) was ~17mm, and that's with a head designed to take larger lifters, etc....and that cam looked HUGE...bearing in mind that's a whole 5mm above a "fast road" cam for that head.

cheers James

__________________

VOC 300-series Register Keeper '13 V70 D4 SE Lux '89 740 Turbo Intercooler '88 360 Turbo Intercooler '84 360 GLT '81 343 GLS R-Sport '79 343 DL '70 164 |

|

|

|

|

|

#43 | |||

|

Rubbing son is racing....

Last Online: Jan 18th, 2017 14:26

Join Date: Nov 2004

Location: London

|

It would be nice to see the full Volvo BTCC engine specs especially the camshafts valve timing, port sizes, angles and valve size info rather than just pictures, but in short running such extreme high lift would IMO dictate minimum weight valves as the further you ask the valve to move the harder it is for the valve train to control it, especially if the cam profile requires acute acceleration and decelerations of the valve, so I guess the BTCC rules may have limited the valve material choices available, hence maybe the ultra thin valve stems?

Speaking generally  max air flow through a cylinder head is normally directly controlled by valve lift until lift exceeds the valves max air flow efficiency, itís then controlled by the capacity of the port configuration, the 25% peak lift ratio mentioned is only a theoretical guide for standard engines which dates way back, engines can and do run higher valve size/lift % but not always for the same reasons. max air flow through a cylinder head is normally directly controlled by valve lift until lift exceeds the valves max air flow efficiency, itís then controlled by the capacity of the port configuration, the 25% peak lift ratio mentioned is only a theoretical guide for standard engines which dates way back, engines can and do run higher valve size/lift % but not always for the same reasons. The standard 2.5 N/A 850 4 valve of that period ran around 27% if my specs are right and obviously we are evaluating this article based on an 8500 rpm limit, anything above this with the correct air flow mass/volume will give more power hence the rpm limits in various racing formulas that donít use forced induction, if we add forced induction into the equation then it gets even more interesting.........................  Or maybe he was just a clever b...............

__________________

Engineer Last edited by Engineer; Sep 5th, 2009 at 20:39. |

|||

|

|

|

|||

|

|

#44 |

|

Senior Member

Last Online: Mar 2nd, 2023 14:47

Join Date: May 2006

Location: Manchester

|

Sorry for the delay! Here are some pictures from the volvo museum

If based on that article the actual BTCC head was a bespoke item I'll see if I can find out what the display engine is. I've got a friend who is going to the Volvo museum in two weeks. |

|

|

|

|

|

#45 |

|

300 Register Keeper

Last Online: Apr 24th, 2024 09:13

Join Date: Dec 2001

Location: Nottingham

|

I suspect the display engine is either a leftover from very early on in the development program (prior to realising that the standard head wasn't going to cut it), or simply a standard engine with some shiny bits bolted on...

cheers James

__________________

VOC 300-series Register Keeper '13 V70 D4 SE Lux '89 740 Turbo Intercooler '88 360 Turbo Intercooler '84 360 GLT '81 343 GLS R-Sport '79 343 DL '70 164 |

|

|

|

|

|

#46 |

|

Senior Member

Last Online: Mar 2nd, 2023 14:47

Join Date: May 2006

Location: Manchester

|

Hi,

The cambelt and pulleys have been upgraded and the belt itself is quite thick. Thereís also an extra oil pump for the dry sump. Curious they open both oil fillers on these heads. Iíve been taking a closer look at the TWR head and the standard one. Seems none of the original casting remains in the TWR head for the race cars. According to regulations, its has the same certain critical measurements and angles but really its totally bespoke. Interesting none the less. I recall Volvoís R division also had some bespoke 16 valve heads for the 240 programme which were later then available for the aftermarket via R-sport division. The 16v head info might not be right but thatís how I recall it. Glad for someone to post more info to correct or refine my answer! James, Iíll PM you about the 2E engine! |

|

|

|

|

|

#47 |

|

Senior Member

Last Online: Mar 2nd, 2023 14:47

Join Date: May 2006

Location: Manchester

|

oops...

just re-read the article. The TWR head is a three piece design whereas the N series head is usually two. TWR has bespoke upper and lower camshaft carriers which then bolt to the remainder of a standard head. |

|

|

|

|

|

#48 |

|

300 Register Keeper

Last Online: Apr 24th, 2024 09:13

Join Date: Dec 2001

Location: Nottingham

|

My reading of the article was that the lower section of the head *had* to be retained...and the reason for the new upper section was to make that 'work' in their application.

I think I'd refer to the 'cover' on the whiteblock head as a piece of the head, given that the upper half of the cam bearing surfaces are machined into it. cheers James

__________________

VOC 300-series Register Keeper '13 V70 D4 SE Lux '89 740 Turbo Intercooler '88 360 Turbo Intercooler '84 360 GLT '81 343 GLS R-Sport '79 343 DL '70 164 |

|

|

|

|

|

#49 |

|

Junior Member

Last Online: Jun 28th, 2016 13:32

Join Date: Feb 2008

Location: Lincolnshire

|

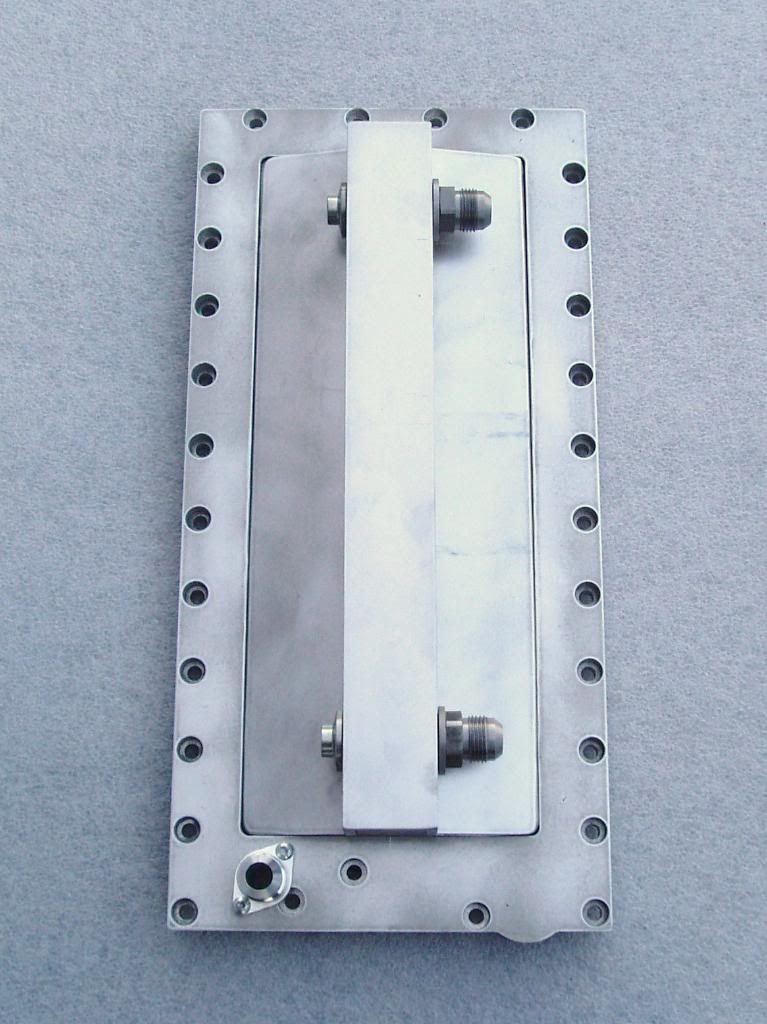

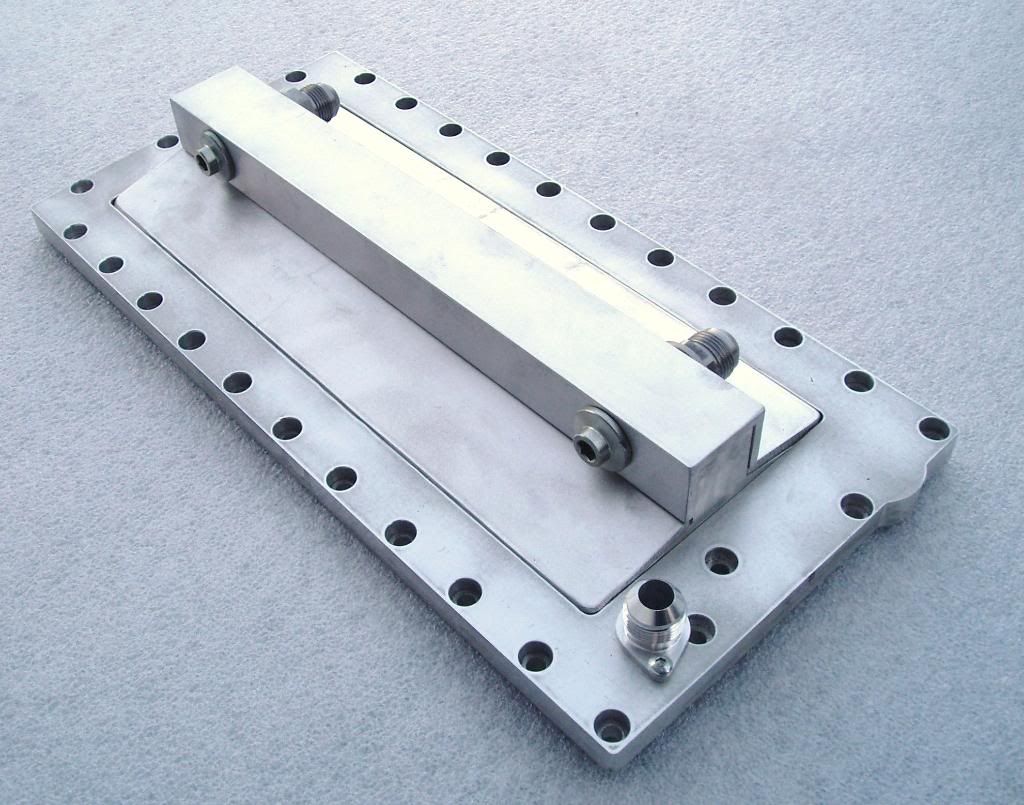

Here are some pics of the sump pan before welding

I have 4 of these to sell if anyone is interested PM me The base plate is 3/4 inch 6082 alloy to keep the rigidity of the block The channel and bottom are 1/4 inch 6082 The Oil take off's are screened fittings made by Pace Products in the UK. These are not cheap so no timewaster please as the cost of components, materials, CNC machining and welding have been high so I want to recoupe my costs in full for making them in the first place Hope you like?

|

|

|

|

|

|

#50 |

|

Junior Member

Last Online: Jun 28th, 2016 13:32

Join Date: Feb 2008

Location: Lincolnshire

|

I have been speaking with Dave Bedborough technical director at MCT who was involved with the development of the original TWR engines used in touring car

Here is the response he gave me Hi Austen I can see you have been busy. I have added some comments to your list as well as these below. Unfortunately I am not too sure what the 5 cyl spec engine is like now as I am referring to the Volvo range from 1996 thru 1999, however we were producing around 325 bhp from a 2.0 litre nat asp version at 8500 rpm in the last season of running. My initial concerns around what you are proposing are as follows: Cylinder Block - the cast in iron linered block distorted badly when the output exceeded 290 bhp. We therefore had to undertake extensive block mods and run slip fit liners to make this work. Crankshaft - are you sure the standard crank is up to the job? We ran a billet steel fully machined crank - weight was around 13kg. We ran a new cam chain drive arrangement on our race engine which enabled us to have better valve train control as well as being able to manufacture a revised front cover to assist engine installation and stiffness. I did wonder why you have run overhead injectors? we did some fairly exhaustive development work and optimised our system with a barrel throttle (mounted close to the head) and in port injectors. We did test overhead systems at various angles but never achieved best power. Your choice of clutch will limit your installed height (unless your ladderframe is excessively deep). We ran a 5.5" triple plate carbon 'pull type' clutch, I am sure you can obtain cheaper alternatives in this size. Best of luck with your project - I hope it is very successful for you. Please get in touch if you need any further assistance and let me know how you get on. Best Regards Dave Here is my initial email, Dave has added his comments to the side of them Dear Dave Further to our conversation this morning, I am currently building a Volvo 5 Cylinder engine for a Westfield Sprint car that I have raced for a few seasons with another engine in it (400bhp turbo motor), I have built quite a few interesting engines over the years so I have a reasonable knowledge of engines. I'm not the typical bodger car buff either as I like things to be A1 pefect to the nut and bolt (I think I'm Autistic) Current spec/mods of what I have already done is as follows Volvo S60 2.0l T5 base engine 35mm inlet valve 6mm stem (we ran a 5mm stem) 31mm exhaust valve 6mm stem (we ran a 5.5mm stem) Trojan guides to suit above double valve springs titanium retainers Larger seats inserted into head Extensive head porting to suit (currently on flow bench so awaiting flow figures) 32mm solid buckets ( we ran 35mm Inlet and 34mm exhaust buckets) Cat Cams Hollow Billet 300 plus deg inlet with over 13.5mm of lift (we had more aggressive profiles max lift 15.5mm) Cat Cams Hollow Billet 290 plus deg exh with over 12.5 mm of lift (13.5mm lift) 13.5:1 high compression CP pistons made to my spec with 83mm bore (we ran on 81mm bores) 2.0l 77mm forged steel crank (standard Volvo item) (not too sure about the longevity of this...) 152mm H section steel rods, give rod ratio of almost 2:1 3 stage Dry Sump system inc billet sump pan made to my CAD drawing (we ran a six stage scavenge) Jenvey tapered inlet system, inc Individual throttle bodies and 10 injectors (remote set firing down trumpets) Billet Steel race flywheel (3.5kg) with 7.25 inch race clutch made to my spec (5.5" flywheel - 1.2kg) |

|

|

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|